Benefits

- Provides more realistic scale predictions.

- Aids selection of injection water.

Background

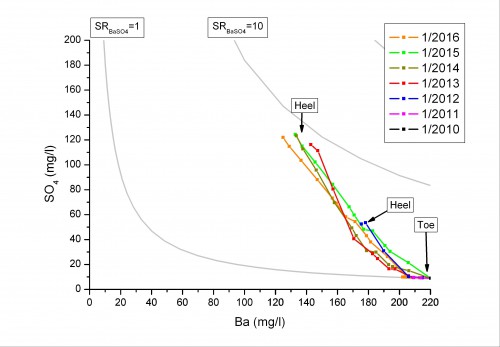

Where water is injected into a reservoir to provide pressure support or to improve recovery, reactions can occur in the reservoir between the injection water and formation water, between mixtures of these and reservoir minerals, and between the injection water and reservoir minerals. These reactions can often result in reduced scaling risks in production wells. For example, deposition of BaSO4 in the reservoir as a result of mixing of SO4-rich injected seawater and Ba-rich formation water can result in reduced produced water BaSO4 scaling risks.

On new developments it can be very beneficial to predict produced water compositions and associated scaling risks after accounting for reactions occurring in the reservoir because:

- More realistic scaling risks can be obtained thereby improving scale management planning. By not considering these reactions, scaling risks can be exaggerated.

- Where selection of a ‘low scaling risk’ injection water (e.g. low sulphate seawater) is being considered as a scale mitigation strategy, incorrect decisions can be avoided. For example, in some cases, after accounting for reservoir reactions the costs of chemical mitigation resulting from seawater injection may actually be lower than the costs of including a sulphate reduction plant on the platform for low sulphate seawater injection.

Consideration of the effects of reservoir reactions on scaling risks is also important when considering a change in the type of injection water on producing fields (e.g. from seawater to low salinity water for EOR purposes).

Where water injection is undertaken, produced water compositions largely reflect:

- The reservoir pressure and temperature.

- The composition of formation water in the reservoir.

- The composition of the injection water.

- Reactions occurring in the reservoir.

- The type of water entering the production well at different locations and their rates of flow (i.e. the flow profile).

Recently, a number of studies (McCartney et al., 2007, Østvold et al., 2010, McCartney et al. 2012; see recent publications) have shown that a limited number of reactions appear to account for most of the ‘reaction effects’ observed in produced water compositions. Interpretation of produced water compositions can indicate what reactions may be affecting produced waters on existing fields.

To aid decision making and planning in the above circumstances and where sulphate-mineral scaling risks are required, we can provide predictions of produced water compositions and these scaling risks.

One approach we use is to integrate reservoir model results and 1-D reactive transport model results (McCartney et al., 2010a; see recent publications). This provides predictions of produced water compositions and scaling risks over time (a) from the well (i.e. water produced from the well) and (b) within the well (i.e. reflecting the changing composition of water produced from the different producing zones).

An alternative approach is to assume that only the injection water is affected by reactions. We then use scale prediction software to predict the range of produced water compositions that could be produced from wells, irrespective of flow profile. This alone may be sufficient to allow correct planning decisions to be made.

BaSO4 scaling risks in a Blane field well after allowance for the effects of reservoir reactions (McCartney et al 2010a)